What is RCD Testing?

Residual Current Device (RCD) testing, also known as RCD testing, involves checking the functionality and performance of RCDs within your electrical system. RCDs are crucial safety devices designed to protect people from electric shocks and prevent electrical fires by quickly disconnecting the power when they detect an imbalance in the electrical current.

Why is RCD Testing Important?

Testing Frequency

Who Should Perform RCD Testing?

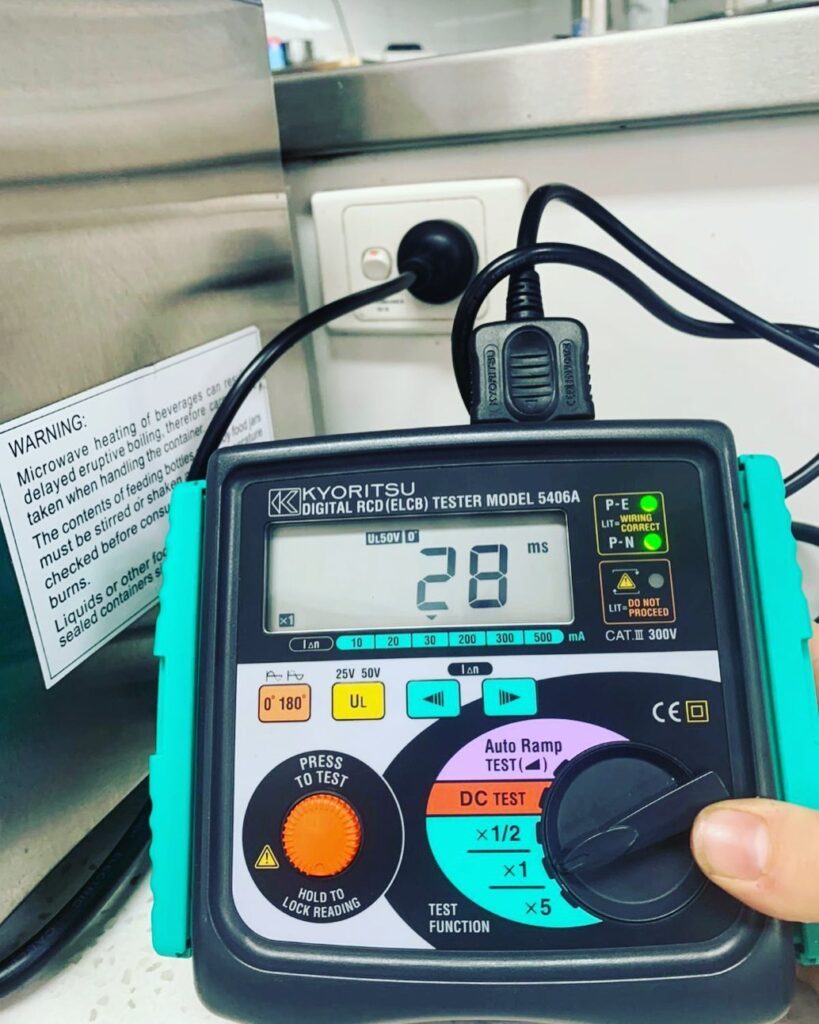

RCD testing should only be conducted by a qualified and trained technician. These professionals have the expertise and equipment necessary to perform accurate tests and interpret results effectively. They can also address any issues that arise and ensure that all testing complies with relevant safety standards and regulations.

What Does RCD Testing Involve?

Conclusion

Regular RCD testing is an essential part of maintaining electrical safety in any property. By ensuring that RCDs are functioning correctly, you not only comply with safety regulations but also protect yourself and others from electrical hazards. Engaging a trained technician for this task ensures that testing is carried out accurately and effectively, helping to maintain a safe and reliable electrical system.

Website Created by IT Solutions Sydney.